SC7800 Pro-RS XL B2+ Automatic Sheet Cutter

Auto-feed digital cutter with revolutionary dual opposing tangential creasing technology

ColorCut SC7800 Pro-RS XL automatic, unattended sheet cutting & creasing, for card, packaging and P.O.S.

SC7800 Pro-RS XL - B2+ wide format version available

ColorCut SC7800 Pro-RS XL sets a new benchmark in automated die-cutting and creasing with its unique triple tool cutting and creasing head for large format press proofing, folder production, packaging and much more!

Triple-tool Digital Die-Cutter, features a tangential wheel creaser (male) and a tangential wheel groove (female) tool – the ultimate digital die cutter ever to be designed! The third tool provides exceptional cutting via a contour drag knife for card, paper and synthetic media.

Highly efficient, ultra-low energy consumption compact sheet cutter/creasers with auto-feeder for rapid sheet production.

Features two modes of operation: DIRECT and HELD

DIRECT mode: Use ColorCut Pro to create your cut files & cut directly from a PC.

HELD mode: Standalone operation. Load repeat jobs to a USB drive, enabling you to remotely cut your jobs anywhere there is power – even using a battery! (NO WIRES).

One cutter – exceptional media size handling

B2+ wide-format Pro-RS XL offers cutting from A3 sheets to larger than B2!

No other device in its class offers so much – and also at such an affordable price!

SC7800 Pro-RS Product information hub:

The NEW ColorCut SC7800 Pro-RS XL sets a new standard for the world’s best digital crease and on a B2 sized digital die-cutter!

Fully automatic, ultra-fast, energy efficient production in a compact and portable footprint.

Targeted for users seeking an affordable, compact, high-capacity cutting solution, the SC7100 Pro-RS XL combines ultra-reliable feeding with an instant job retrieval system and flawless high-speed cutting and tangential wheel and groove creasing for complete unattended production.

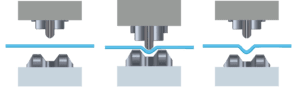

- Smooth, deep creasing with its dual opposing tangential creasing wheel (male) and female tangential creasing groove wheel

- Digitally cut-through any shape sheet card item – with SmartTag retention – on up to 450 micron media

- Run jobs from USB drive or PC

- Cut speeds up to 1060mm/sec

- Crease force delivered using a dual opposing tangential creasing wheel & groove wheel for up to 2.5kgf (2,500gf)

- Cut force up to 1kgf

- Digital process means no more costly dies or wasted waiting time

- Auto feeder stacks up to 1,000 80gsm sheets. Up to 520mm (20.5″) x 740mm (29″) and custom sizes – with self-centring function and Airblade2© separation

- ColorCut Pro – Production Studio software included

- QR code/Job Library retrieves associated cut files – even for mixed job batch sessions or rotated sheets

- SmartMark registration delivers incredible accuracy – enabled via the supplied ColorCut Pro software

- Optional Server Station expands workflow capability and offers additional software for instant box/carton templates

The SC7800 Pro-RS XL model blends cutting and creasing abilities of flatbed technology with automatic sheet fed functionality – all within a precision engineered, compact free-standing unit with an easily manoeuvred ergonomic space saving design.

Averaging under 140W of power consumption, the SC7800 Pro-RS XL is also possibly the most energy efficient and lowest operating cost cutting solution in it’s class. The ability to operate machines from a 7″ Touch panel in HELD mode, with the NO WIRES functionality means this mobile device can be easily accommodated in any print shop or manufacturing company that needs to die-cut and crease card.

Complete standalone operation – even with a stack of mixed jobs

- In today’s fast-paced print environments, the SC7800 Pro--RS utilises a 9th generation Vision3 CCD camera delivering a remarkable production edge. It reads and retrieves cut files for every sheet instantly and on the fly, enabling true unattended production. The system can process a mixed stack of jobs, cutting each one in sequence for a smooth, uninterrupted workflow.

- Its QUAD ‘Grip and Drive’ feed system secures the media on both sides of the cutting head, allowing it to cut much closer to the sheet’s edges than most other sheet cutters.

- The revolutionary cutting strip – adapted from the advanced cutting mats used in Intec flatbeds – provides the ideal surface for cut-through, creasing, and kiss-cut applications, perfectly complementing both production tools. Because each sheet remains in constant high-speed motion, only minimal SmartTags are left in the cut lines to keep items securely in place, resulting in a neat, easily manageable stack of fully finished sheets in the catch tray.

- The high-capacity auto feeder works in seamlessly with the NEW Airblade2 separation system and automated jog function to ensure every sheet is perfectly presented to the cutter, every time.

- ColorCut Pro Production Studio software supplied as standard, instantly generating all necessary production marks and delivering exceptional digital efficiency for both designers and machine operators.

Media handling:

SC7800 Pro-RS XL

A3 , Tabloid, SRA3 & Tabloid Extra, 13″ x 19″ and custom sizes up to B2+ sheet size

Custom media sizes: Media width (min-max): 279mm x 520mm

Media length (min-max): 400mm x 740mm

Job recognition:

Advanced QR code technology for instant file recognition and registration

Stand: included

Media storage: lower media trays in included stand

Media thickness: 200 micron (0.20mm ) – 450 micron (0.45mm)

Auto-sheet capacity: Up to 1,000 sheets (based on 80gsm) 15kg | XL 30kg

CUTTING CONTROL

Mountable tools: Triple tool functionality – 3 tools supplied as standard:

Blade holder – holds cutting blades; 30º, 45º or 60º for range of media types

Creasing tool – Tangential wheel creaser (male) and Tangential Creasing Groove (female), suitable for ≤450 micron card and other optional widths available

Calibration pen – pen, plotting pen used for auto-calibration.

Crease force/pressure: up to 2,500gf delivered in 190 steps programmable through Intec ColorCut Pro cutting software

Cut force/pressure: up to 1,000gf delivered in 190 steps programmable through Intec ColorCut Pro cutting software

Maximum speed: up to 1060mm/second

REGISTRATION CONTROL & JOB MANAGEMENT:

Registration system: Vision3 – High resolution CCD vision system reads the registration marks on the media and compares their position to the original digital file, automatically adjusting the cut lines to correct for any scale or skew variations

Cut position accuracy: +/- 125 micron

Auto job recognition: Instant cut file retrieval, supported through QR code job recognition in conjunction with ColorCut Pro 5 software (supplied)

POWER REQUIREMENTS

Power supply: 100-240V 50/60Hz, 140W Avg. (320W peak)

Approvals: Complies with CE and RoHs directive

GENERAL

Weight: 210kg

Dimensions: W1050 × D860 × H1256mm

Max’ area required in use: W1013 × D1740 × H1256mm (working depth includes front media catch tray and rear extendable media tray)

Varied or mixed job recognition: QR reading provides capability to stack mixed jobs and cut at same tim

ColorCut Pro Production Studio

ColorCut Pro Production Studio is the core software application used with all ColorCut models and provides a plugin, that can be installed on remote computers anywhere within the workflow environment, to perform contour cutting of paper card and synthetics.

For creatives the application enables artworkers to generate QR coded cut files with unique job numbers, as an integral part of their design, for instant job recognition and file retrieval.

For print finishers the ColorCut Job Library stores all the cut files created during the design stage, allowing operators to quickly pull up previously prepared files without opening Adobe® Illustrator® or CorelDRAW®. This is especially useful in production environments that operate separately from the design studio.

What makes the SC7800 Pro-RS XL so different from other digital die-cutters on the market?

Designed to fill a real market gap:

Intec listened to customers who were frustrated by the choice between basic, low-cost cutters (that couldn’t crease and struggled with feeding) and high-end systems far outside their budget.Engineered to outperform expectations:

Intec invests heavily in R&D to create a highly capable, extremely affordable solution—delivering far more than its price tag suggests.Revolutionary NEW tools with faultless feeding:

The SC7800 Pro-RS XL features a revolutionary NEW type of creasing using opposing tangential creasing tools; a male creasing wheel and a female groove wheel. This provides a crease/fold much like you will receive from a metal rule platen. Cutting is provides by a contour cutting knife tool for cut through applications on FBB, SBB cards, synthetics and much more! Its ground breaking suction-belt pick-up technology provides near faultless sheet feeding. It also includes a massive 1,000-sheet automated stacker for non-stop productivity.Top-tier performance at an accessible price:

Remarkably, the system comes in around the same price point as inferior entry-level cutters—yet offers capabilities they simply can’t match.

What does automatic actually mean?

Once the job is set up, the SC7800 Pro-RS XL takes over—feeding and cutting completely unattended. Just load the stack and let it run.

How does the automation deal with mixed jobs?

Thanks to its intelligent software and Vision3 CCD camera, the cutter reads a QR code printed on every single sheet and instantly loads the cut file associated with that job.

Jobs can be mixed in the stack in any order – even if sheets happen to be placed into the stacker at 180°, the system still processes them flawlessly.

Will this machine crease card as well as cut it?

Absolutely! The tool head carries both cutting AND a creasing tools, delivering up to 2,500g of creasing force and 1,000g cutting force – the strongest in its class.

Through the provided ColorCut Pro software, you can cut, crease, perforate and score any shape, with full control over force, speed and the task in the user’s preferred running order.

Does the SC7800 Pro-RS XL kiss-cut labels as well?

The SC7800 Pro-RS XL is purpose-built for large-format sheet work, featuring four powerful grip rollers that deliver exceptional media control and advanced feeding—allowing precise cutting right up to the sheet edges. This robust design makes it ideal for high-accuracy cut-through and creasing applications on larger sheets.

For customers requiring high-quality kiss-cut label production, Intec offers a dedicated range of sheet-label cutters within the ColorCut Series, specifically engineered to deliver outstanding kiss-cut results efficiently and consistently.

How easy is the SC7800 Pro-RS XL to use?

All our products are designed with simplicity in mind and intuitive to use. We supply appropriate training for every machine we manufacture. This can be delivered face-to-face at your premises or via remote platforms. A full library of manuals, guides and helpful videos is available, along with direct access to Intec’s technical support team wherever needed.

Intec also maintains extensive stocks of consumables and spare parts for fast, same-day dispatch but always advise local holding of these is a preference.

What support can I expect?

All our products are designed to be intuitive and as simple to use as possible. We supply appropriate training for every machine we manufacture. This can be delivered face-to-face at your premises or at one of our offices. We can even supply remote support via Teams should that be more agreeable. We also have a library of downloadable manuals and help guides to refer to and a series of useful videos.

Our technical support team are also available to assist our customers when required.

Large stocks of consumables and spare parts ready for same day shipping are kept locally with regional partners.

Cut, crease & perforate

Perform any shape cutting and creasing on up to 450 micron paper/card.

Blending flatbed precision with sheet-fed speed, the ColorCut SC7800 Pro-RS XL delivers effortless digital die-cutting and creasing for cartons, packaging, P.O.S. cards, and paper projects. Its opposing male and female tangential creasing tools create the most precise, cleanest creases of any digital sheet cutter in the world, ensuring professional-quality folds every time.

Designed for on-demand production, it eliminates dies and setup costs, making it ideal for busy print departments. With ultra-reliable auto-feeding, instant job retrieval, and fast, flawless cutting, the SC7800 Pro-RS XL provides high-capacity, fully unattended sheet finishing with maximum efficiency and unmatched crease quality.

SC7800 Pro-RS XL automatic sheet cutter features 2.5kg tangential crease 1kg cut force...

Unique in its class – World’s first male / female creasing digital die-cutter

Create flawless creases of any shape with the World’s first machine that features a male and female crease tool.

Triple tool head – includes Passive Drag cut and Active male and female tangential creasing tools for an enhanced and superior crease. The result is a cleaner, deeper, and more professional crease—simply unmatched in its class.

The wheel creasing tools are used to produce excellent creasing on printed sheets. This can be set to perform its tasks before the cutting process and will also exactly match the designer’s vector artwork.

Industry-leading software!

Intec’s ColorCut Pro Production Studio 5

ColorCut Pro Production Studio 5 software is supplied, as standard, enabling you to use Adobe® Illustrator® or CorelDRAW® for your cut file creation.

Add the optional ColorCut Pro Server Station to maximise your workflow and productivity. The Server Station comes pre-installed with additional ColorCut software; Template Maker which offers users bespoke cut file generation of carton box designs and Job Library Manager for file cutting control.

Ultra-reliable!

High-capacity and ultra-reliable feeding.

The SC7800 Pro-RS XL is engineered for reliable, unattended production, with a class-leading feeding system designed to handle card, vinyl labels, and even challenging laminated sheets. Its innovative suction feed belt works alongside air blade separation to accurately lift and feed each sheet, while the jogging back wedge keeps media perfectly controlled. With continuous, dependable feeding from the 1,000-sheet stacker, high-volume production runs smoothly and confidently.

Cut mixed jobs

QR coded sheets enables automatic cut file retrieval.

No skilled operator required for cutting! When creating jobs, ColorCut Pro applies an auto-assigned (editable) QR code to each design, whilst auto-saving the cutting file to the ColorCut Pro Job Library. The CCD video camera within the tool head reads the QR code as each sheet is presented and instantly retrieves the associated cut file.