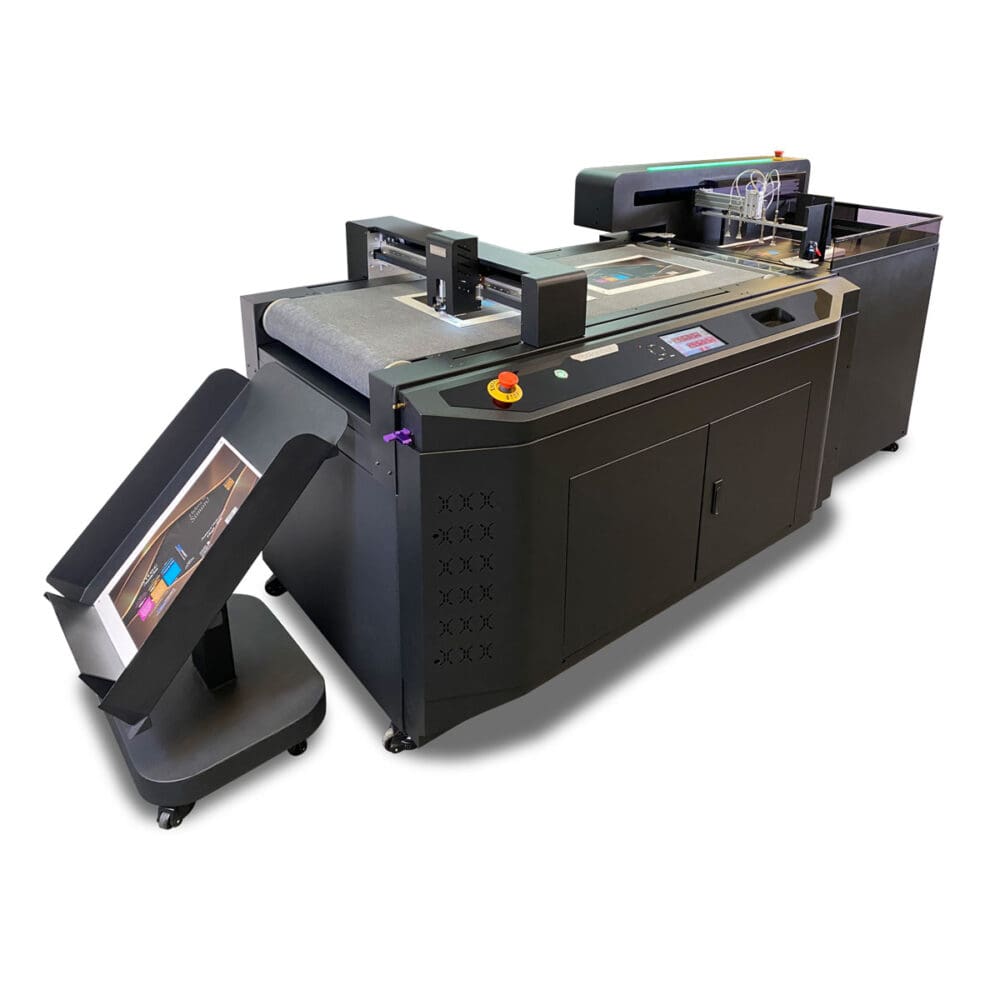

FB9500 Pro-T Automatic Tangential Creasing Digital Flatbed Cutter

Exceptional creasing and precision cutting.

The FB9500 Pro-T is a fully automated, tangential creasing digital die cutter delivering lightning-speed performance, unparalleled media control and highly sophisticated, but user-friendly production functionality.

Ideal for high quality packaging, point of sale and label production the ultra-fast FB9500 Pro-T incorporates the latest technology with patented back mark reading so any print boards can be finished with confidence. The FB9500 Pro-T delivers the speed and accuracy required by today’s leading designers, printers and manufacturers.

Advanced component technology delivers creasing forces of up to 2.5kg and a cutting force of up to 1.3kg – perfect for media up to 3,000 microns.FB9500 Pro-T Product information hub:

- Digital process allows cutting and creasing for any shape or design from one sheet to another automatically

- QR code driven workflow – simple to operate using the QR code file retrieval for mixed or batch job production

- SmartMark registration delivers incredible accuracy using ColorCut Pro software, supplied with the system

- Fully optimised feed system – advanced sheet separation processes, allow accurate and trouble-free feeding, for fully unattended operation

- Sheet pre-placement – whilst cutting and creasing, the FB9500 Pro-T will place the next sheet ready for production. This reduces the feed time and boosts productivity making the FB9500 Pro-T one of the fastest systems available on the market today

- Patented Rear Mark Scanning System – optimise your creasing quality for certain jobs by creasing the back of the sheet without having to print marks or QR codes on both sides

- 2.5kg of creasing pressure – more pressure produces deeper more defined creases for a high-quality finish

- Optional perforation wheel and tangential blade

Creative on-demand digital print finishing, prototyping and production for packaging and POS.

Intec’s advanced, fully automated digital die cutter delivers lightning speed performance, unparalleled media control and highly sophisticated – but user-friendly – production functionality.

The dual tool head houses the active tangential creasing tool and passive cutting tool allowing you to cut and crease in one simple operation. Applying a creasing force of 2.5kg the tangential creasing wheel provides smoother more defined creases for high-quality applications. The versatile passive blade can produce a range of actions including cut, tab, kiss cut, perforation and scoring. This combination of tools provides for a wider range of media handling.

SPECIFICATION

Max media area:

(auto sheet feed) 500mm x 720mm

(manual placement) 550mm x 850mm

Effective cutting area:

(auto sheet feed) 483mm x 700mm

(manual placement) 495mm x 735mm (no mark scanning)

Registration system:

High speed CCD Camera

Job recognition:

Advanced QR code technology for instant file recognition and registration

Stand: integral and included

Media hold down method: 2 zone vacuum bed (High speed 750W vacuum pump included as standard)

Acoustic cover for pump: yes

Acoustic features: Acoustic cover/housing for vacuum pump, silencer for vacuum pump intake

CUTTING CONTROL:

Mountable tools: Tangential Creasing Wheel with optional interchangeable wheels.

Blade holder tool for a selection of blades.

Optional: Perforation Wheel and Tangential Blade Holder and blades

Force/pressure:

Tool 1 (Crease) up to 2,500gf (2.5kg)

Tool 2 (Cut) up to 1,300gf (1.3kg)

DIMENSIONS:

Uncrated: Length: 3,140mm (123.62″) Height: 1,225mm (48.22″) Depth: 1, 095mm (43.11″)

![]() Coming soon.

Coming soon.

ColorCut Pro Production Studio

ColorCut Pro is a stand-alone application with a plugin, that can be installed on remote computers anywhere within the workflow environment, to perform cutting and creasing of paper card and synthetics. Intec supplies this with all ColorCut models to offer a complete turnkey solution.

For creatives the application enables artworkers to generate QR coded cut files with associated job numbers and page marks, as an integral part of their design, for instant job recognition and file retrieval.

For print finishers the ColorCut Job Library enables users to retrieve previously prepared cut files into their workflow, without the need to launch Adobe® illustrator® or CorelDRAW®. This is typically used in a production environment, remote from the design studio.

Flagship digital die-less cutting

The ColorCut FB9500 Pro-T Automatic Digital Die Flatbed Cutter is our latest addition to the premium models

The FB9500 Pro-T is a highly advanced digital die flatbed cutter that can operate at speeds of up to 1,200mm per second, delivering ground-breaking cutting and creasing forces – and performing on media up to 1,000 microns!

Stack and set the FB9500 Pro-T to run unattended, cutting and creasing almost any printed promotional item, to absolutely any shape! Supporting digital print industry-standard SRA3 (Tabloid Plus) media, the system can also run larger media (SRA2 and up) when required. Another advanced feature is its ability to feed in either landscape or portrait mode. Automatic Digital Die Flatbed Cutter

Set up, stack, and produce!

Free-up valuable operator hours by letting FB9500 Pro-T do the work for you… The auto sheet feeder delivers precise media handling and can stack up to 25kg – up to 2,000 sheets of printed media. The FB9500 Pro-T Automatic Digital Die Flatbed Cutter uses the high-resolution Vision3 CCD camera to scan registration marks and also read QR codes to identify and automatically retrieve the associated cutting file from the ColorCut Pro’s Job Library. Easily run a stack of mixed designs – the supplied ColorCut Pro software will faultlessly retrieve each cut file for each sheet in the session.

Crease at forces up to 2.5kg and cut with up to 1.3kg of force

Free-up valuable operator hours by letting FB9500 Pro-T do the work for you… Tackle heavier-weight projects at ease with FB9500 Pro-T’s superior functionality! The advanced components and technology incorporated within the FB9500 Pro-T deliver the best creasing possible with the NEW tangential creasing wheel and expand the range of media options and project types that can be cut & creased.Stack and auto-feed up to 2,000 sheets

Advanced AirBlade technology ensures media separation for perfect feeding.

High-capacity stacker/feeder features quad (4) pneumatic suction pick up for media. Sheets may be placed in either portrait or landscape orientation. Potential stray media is returned to the stack thanks to air pulse knockdown nozzle assembly.