ColorCut Pro software

and the optional Server Station

Intec has developed and produced dedicated ColorCut Pro software that ships with our digital die cutters. This optimises contour cutting capabilities and helps users cut projects with simplicity and precision.

ColorCut Pro explained

ColorCut Pro is a stand-alone software application with a plugin, that can be installed on remote computers anywhere within the workflow environment, to perform contour cutting of paper card and synthetics. Intec offers a complete turnkey solution because we manufacture both the hardware and develop the software for our range of ColorCut flatbed machines. For creatives, the core application enables artworkers to generate QR-coded cut files with associated job numbers, as an integral part of their design, for instant job recognition and file retrieval. For print finishers the ColorCut Job Library enables users to retrieve previously prepared cut files into their workflow, without the need to launch Adobe® Illustrator® or CorelDRAW®. This is typically used in a production environment, remote from the design studio, and may be further enhanced if using the optional Server Station. Software development. Intec currently offers two modes within its ColorCut Pro 4 and 5 software, both delivering the same operator functionality but differing in the way it generates and reads the data. ColorCut Pro 4 and 5 automatically generate either a QR code for cutters with onboard Vision3 CCD camera, to read and cut digital files. The software is supplied with each flatbed cutter and fully integrates with the leading drawing packages; Adobe Illustrator and CorelDRAW.

Contour cut with ColorCut Pro

The onboard sensor/camera reads the generated barcode or QR code on each printed sheet and retrieves the associated cutting file from the ColorCut Pro Job Library. The user can also key in the job number to pull up cut files should there be a need to remove these from the printed sheet for artworking purposes.

The onboard sensor/camera also reads the registration SmartMarks for positional accuracy. Advanced features compensate for print skew or positioning skew to ensure precise cut registration.

Create and modify. Being fully integrated with Adobe Illustrator and CorelDRAW, ColorCut Pro4 or 5 (depending on machine) allows users to re-open artwork that requires design elements to be edited. Once edited, simply recreate a new cut file and its data with a keystroke.

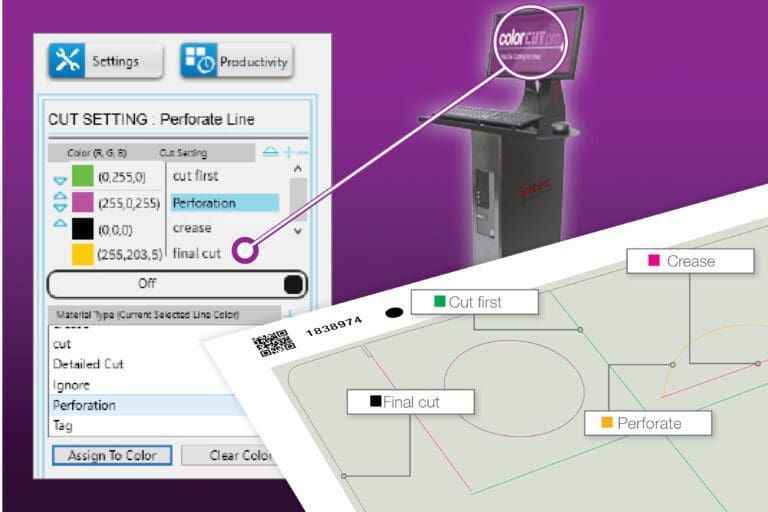

Colour recognition. Working with vector lines in the design, it is possible to set up cutting/ creasing processes using different line colours. This feature recognises different colours and allows users to set types of operation and the sequence, by colour.

Productivity controls for production runs. Multiple sheets can be placed on the table at the same time and ColorCut Pro can be set to search for each sheet and cut it – improving productivity.

Smart Line control. There is no need to draw different types of lines in your artwork, such as dotted or dashed. Using a solid vector line is all that is required. By specifying given lines in certain colours, ColorCut Pro can be used to designate the required tasks to each line colour i.e. red to cut, blue to perforate, green to crease etc.

For complex designs, it is possible to change the cutting sequence and order – for example; cut all hanging slots as the first task, perforate the dispensing hole as the second task, then next perform all creasing or cut outer shape as the final task, etc. This feature can also be used to good effect if the finished item is to be retained within the sheet – simply set the final cut task to contain small ‘tags’ to hold the design in place.

Origin the sensor and click start. With ColorCut Pro, once the cutting head is positioned on the first registration mark and the origin point is set, the flatbeds sensor will automatically detect the sheet’s 2nd, 3rd and 4th registration marks and compensate for any scale, skew or positional errors – cutting will then automatically start.

Server Station. Maximising workflow & productivity for ColorCut users

The innovative features of Intec’s ColorCut Server Station will streamline the entire cutting process, increase workforce productivity, reduce costs – and increase profits.

Whilst the ColorCut Pro software supplied with each cutter can be used to simply cut files directly from the user’s desktop – high-productivity environments will certainly reap the rewards provided via the automation that the Server Station offers!

Intec ColorCut Server Stations are the central hub of ColorCut’s cutting ecosystem – connecting to each networked graphic designer’s system and integrating with the print/finishing room for seamless workflow automation.